FORGIERA FORGED

MANUFACTURING

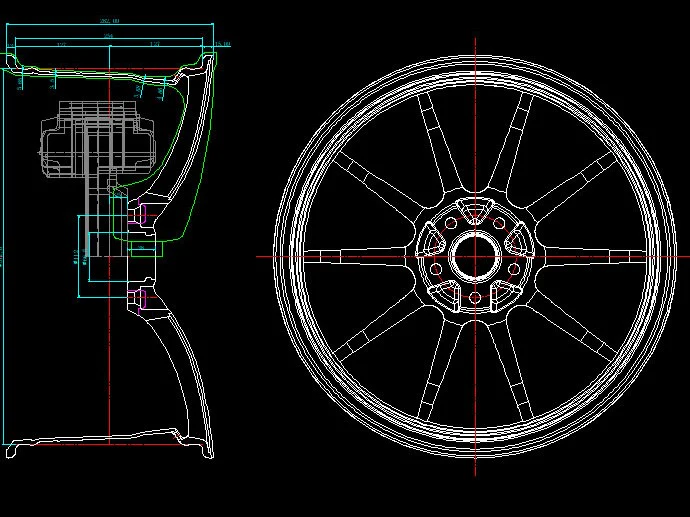

STEP 1 PROGRAMING

Each FORGIERA wheel is designed in a computer-aided design (CAD) program and we run them through rigorous computer simulations in order to stress-test your design, pinpoint potential stress-points, predict its performance and ensure it is in compliance with all safety standards.

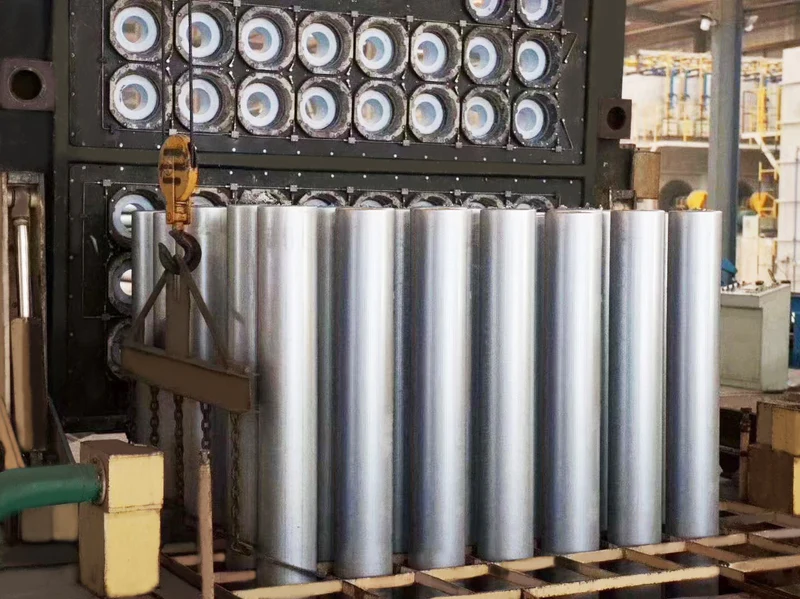

STEP 2 MATERIAL : ALUMINUM RODS

Aluminum rods for forged wheels are typically made from high-grade aluminum alloy. These rods are specially designed to be lightweight, strong, and durable, making them ideal for forging into wheels. FORGIERA Fully Forged Wheels are made of aerospace-grade forged 6061-T6 aluminum alloy, a material of the highest quality, producing stronger and lighter wheels.

STEP 3 THREE-STEP FORGING PROCESS: 12,000 FORGING LINE

The aluminum rods will be proceeded to FORGIERA 12,000-ton forging line which meets the highest standard in the industry for processing to forged blanks, we adopt the most advanced and mature three-step forging process to ensure product quality. Be aware of foring line claiming to be "10,000-ton" or "8,000-ton",which the hardness and strength of its wheels are far less than 12,000 tons.

STEP 4 FORGING BLANKS

After the initial forging and forming forging process, we are able to obtain a forged blank that is suitable for each model.

STEP 5 CNC MILLING : INITIAL PROCESSING

Next, the forged raw billet is placed in a lathe, on which the top layer of metal is removed. Once the perfect profile is achieved, the wheel is transferred to the CNC machine.

STEP 6 CNC MILLING: PRECISION MACHINING

In this production phase, the material is gradually removed from the stock material to create the final product. FORGIERA factory uses high-custom Japanese CNC machines to create intricate shapes and details with a high degree of accuracy. The process involves a cutting tool, typically a milling cutter, which rotates and moves along multiple axes to create the desired shape.

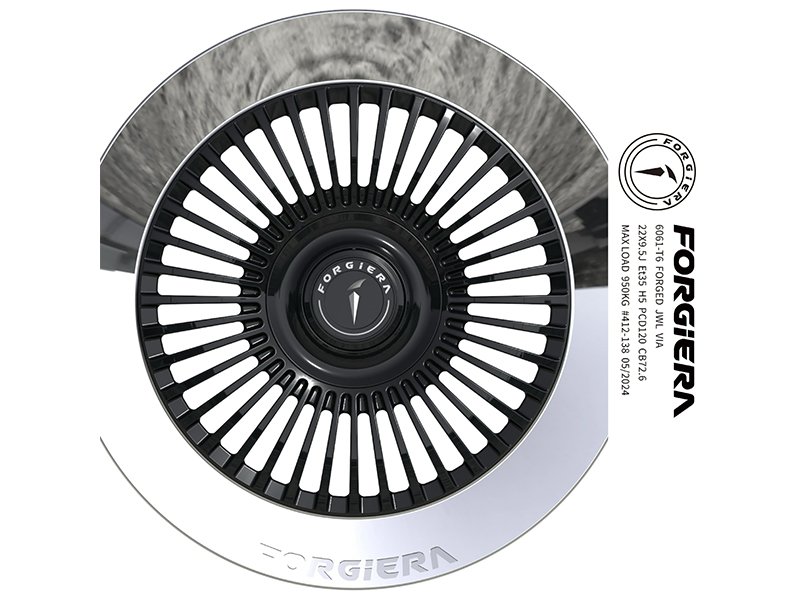

STEP 7 ENGRAVING

Each wheel's specifications, such as wheel size, offset, center bore, and maximum load, are engraved on the inner rim, marking each new wheel as a true one-of-a-kind forged product.

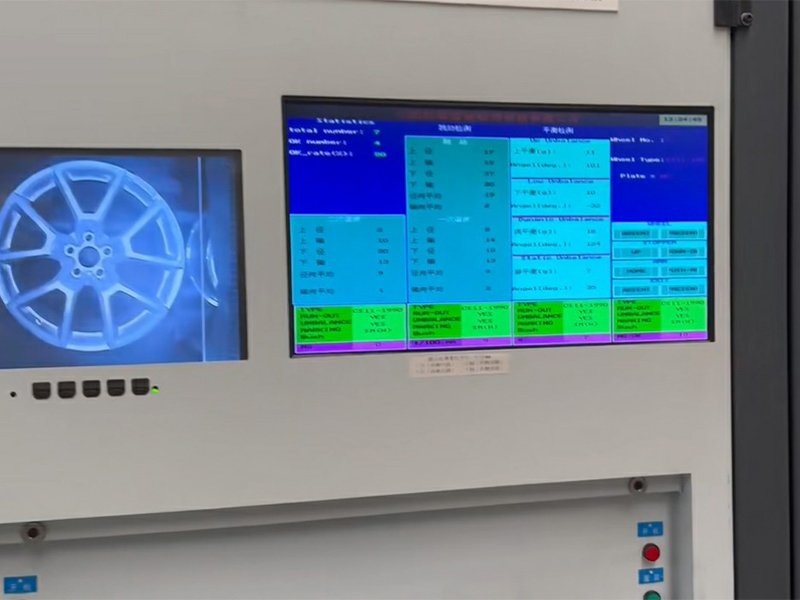

STEP 8 QUALITY CONTROL

FORGIERA quality control team confirms every critical dimension according to detailed engineering schematics. After ensuring that the products pass the three internal tests(Bending test, Rolling test, Impact test ), the products will be sent to the FORGIERA laboratory for testing and certification as required. Each FORGIERA Forged Wheel meets the world’s highest standards in the industry

STEP 9 MANUAL PROCESSING

Before the painting stage, each wheel is inspected and prepared manually. The brushed and polished wheels are further hand-crafted to create a unique custom look.

STEP 10 FINISHING

After machining, the wheel is ready for a finishing process. FORGIERA Forged Wheels are offered in a vast array of powder-coated finishes, brushing, polishing and chrome finishes. All wheels are held to the highest standards of finish quality. We adopt a specialized powder that is electrostatically applied to the wheel and then cured in an oven. This creates a tough, durable finish that is resistant to scratches and fading which provides superior protection and an attractive finish to forged wheels.

WHEELS COLORINGIN

ANY COLOR AND TEXTURE

The FORGIERA team is always inventing and researching new colors or combinations of them, as well as offering our customers some truly unique combinations that stand out from the crowd.